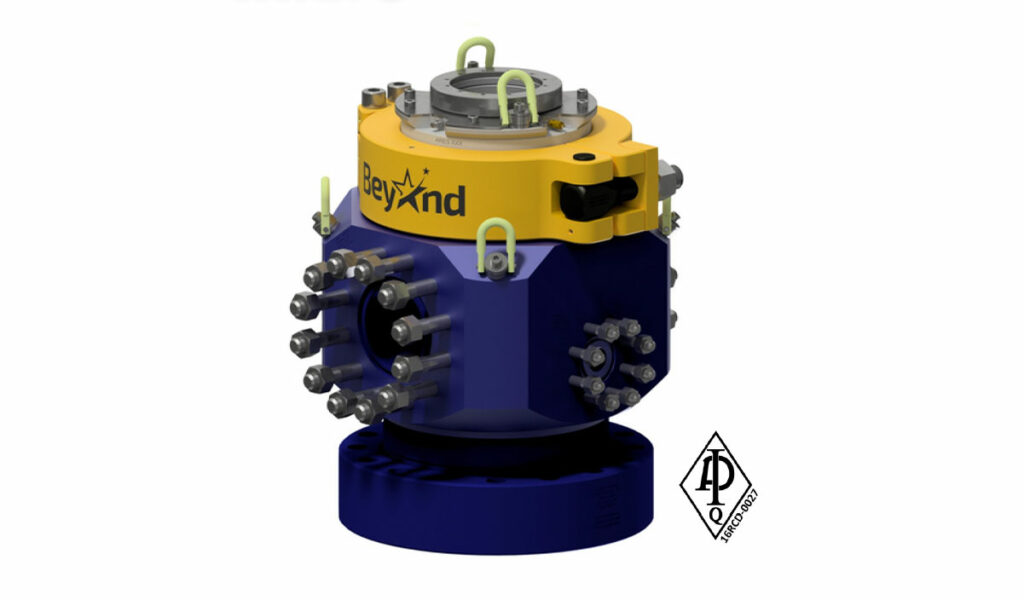

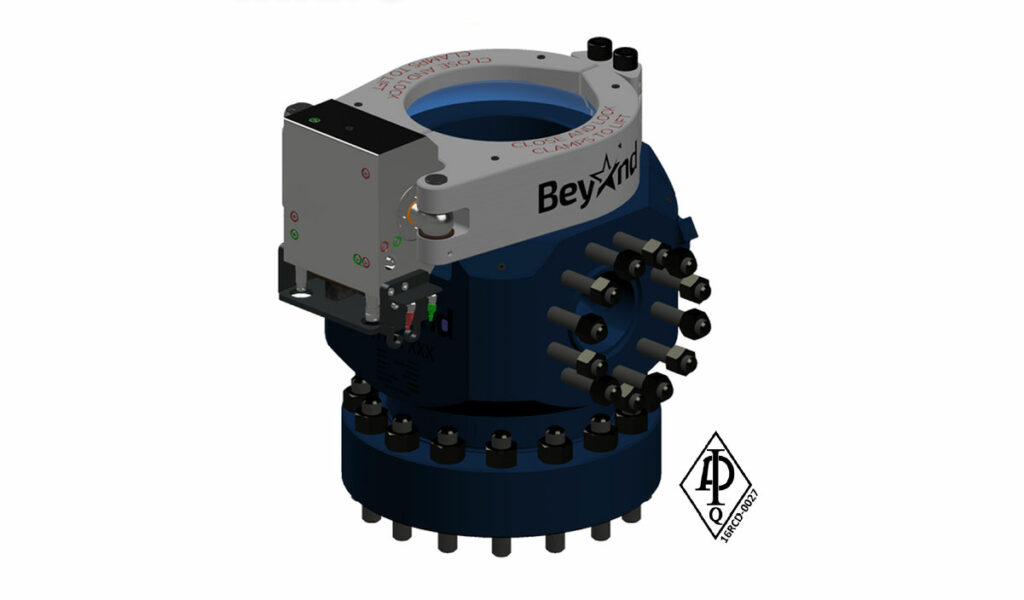

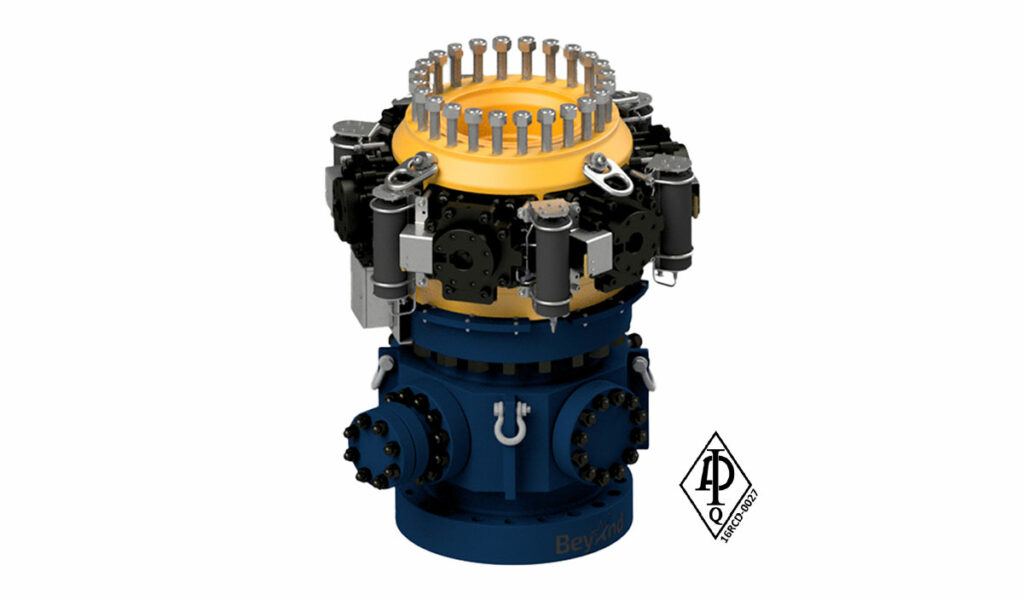

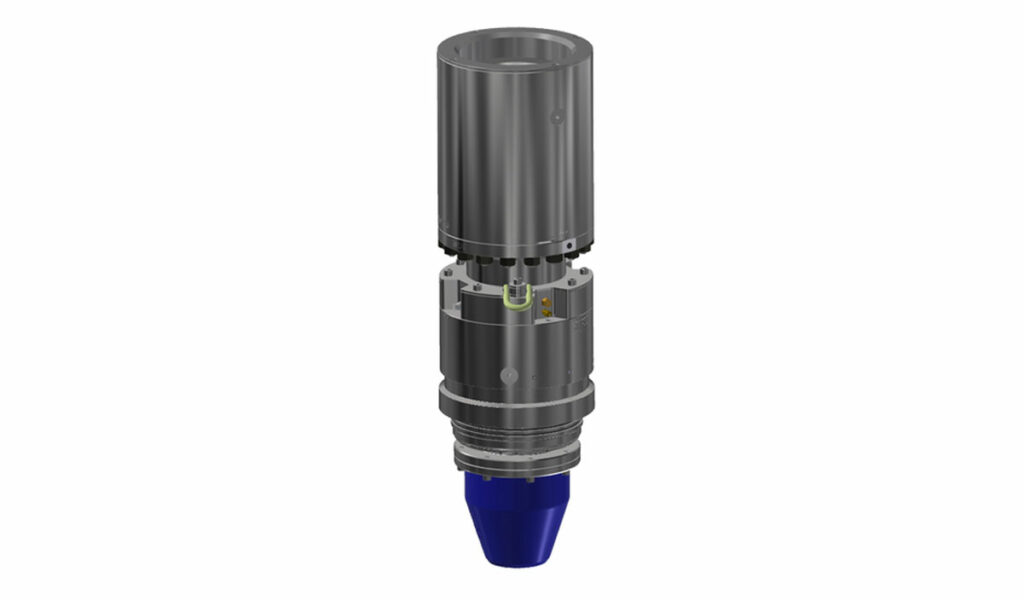

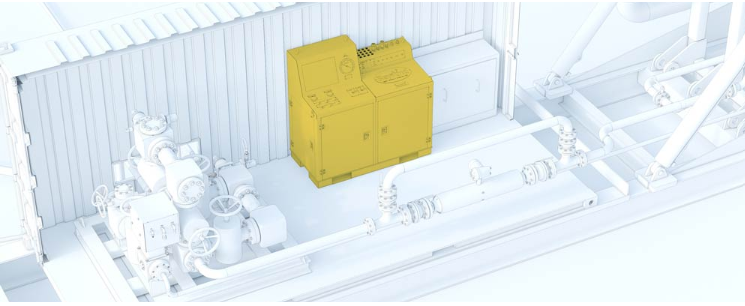

NITRO MPD™

This is Beyond’s flagship system package that is a fully loaded MPD system intended for truly challenging MPD applications. This system incorporates advanced Hydraulic models to control downhole ECD during drilling and tripping operations with pinpoint accuracy and is perfect for drilling narrow window wells. It allows for early event detection against kicks and losses and includes our patented Nitrogen BackPressure system. This feature ensures you retain dynamic control of your well even in static well conditions such as connections or power loss at the rig.