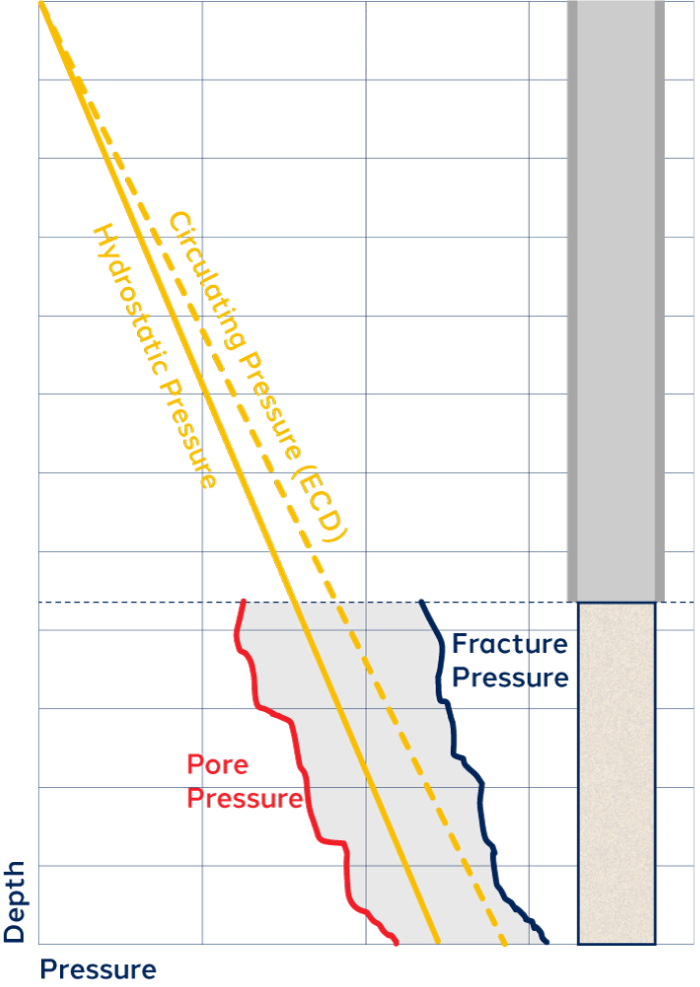

Conventional Drilling:

In conventional drilling, the well drilling system is open to the atmosphere at the top.

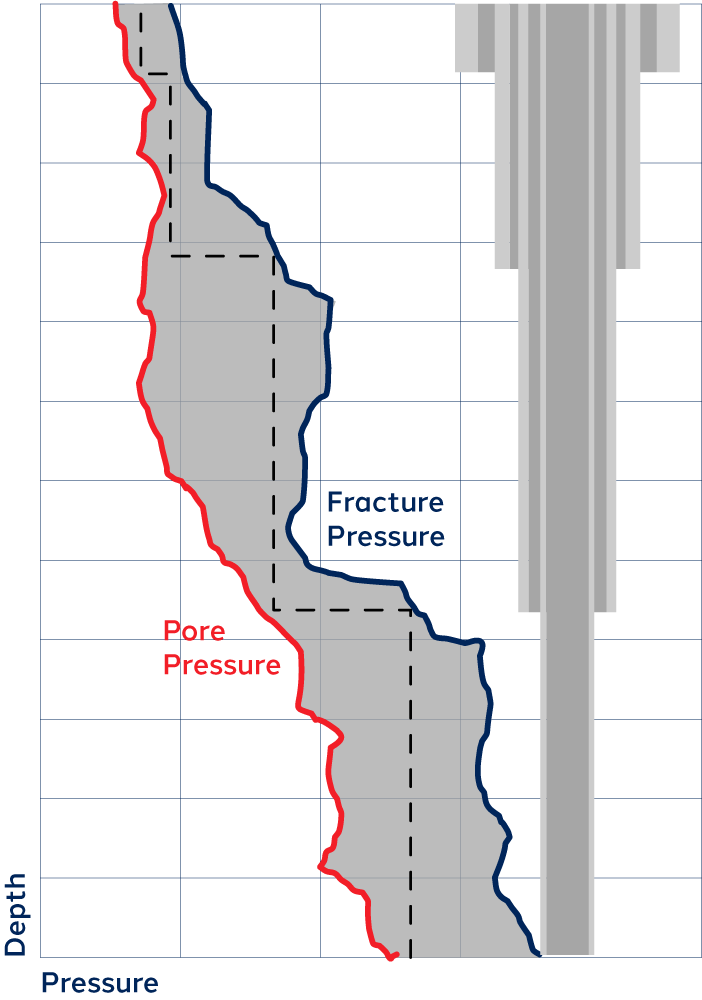

- This creates two profiles:

- The static one which is due to the drilling fluid hydrostatic pressure (solid line)

- The dynamic or circulating one due to the hydrostatic pressure plus the pump pressure necessary to circulate the fluid into the wellbore (dotted line). This one is called Equivalent Circulating Density or ECD.

- One of the limitations of an open system is that the pressure profile always starts at zero at surface.

- There is also a difference in the pressure at the bottom caused by the added pressure when pumps are on.